Microspeakers is a growing segment as the audio market expands with an increasing number of wireless headphones and cell phones available. These high-value speakers face ever-increasing demand to improve sound performance while minimizing space requirements – goals that can be achieved with the same family of soft magnetic alloys used to power electric vehicles.

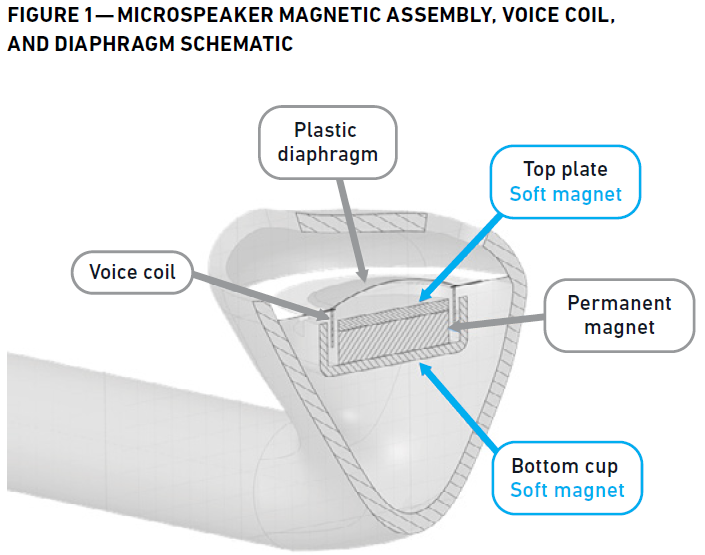

The dynamic drivers inside microspeakers consist of a permanent magnet surrounded by two soft magnetic components, attached to a diaphragm and the voice coil. Not only do these components drive performance, but they also take up much of the space within the assembly. Optimizing these can therefore lead to an increase in sound intensity while reducing assembly size. Using a high-induction soft magnetic alloy can help designers achieve these goals.

The industry-leading magnetic induction of the Hiperco® family of iron cobalt alloys increases magnetic flux in the voice coil to increase force and, ultimately, sound pressure level (SPL). A transducer can be reduced in size by 30% while maintaining the same SPL utilizing Hiperco instead of the commonly used 1008/1010/1018 steel, or the sound intensity can be increased if desired the same design footprint is kept with a drop-in solution. Voice coils from these iron cobalt alloy solutions also require less operating current to produce the same SPL levels, which translates to increased battery life – a key benefit to consumers of electronic devices.