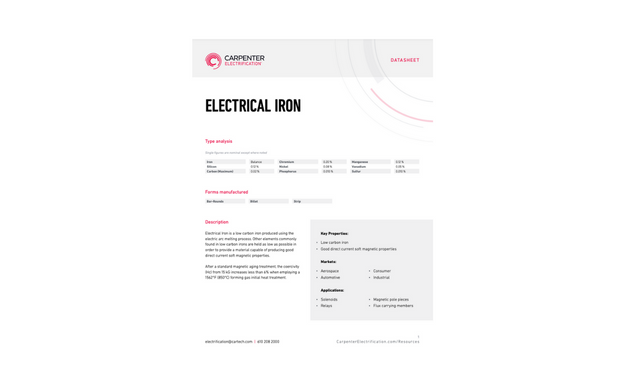

Robust Direct Current Soft Magnetic Properties

Other elements commonly found in low carbon irons are held as low as possible in order to provide a material capable of producing good direct current soft magnetic properties. After a standard magnetic aging treatment, the coercivity (Hc) from 15 kG increases less than 6% when employing a 1562°F (850°C) forming gas initial heat treatment.