PRODUCTS

Build your advantage using our high-performance soft magnetic alloys and stator and rotor stacks.

Build your advantage using our high-performance soft magnetic alloys and stator and rotor stacks.

Advancing electrification through high-performance solutions for power-dense motors.

Creating solutions that enable the electrification revolution

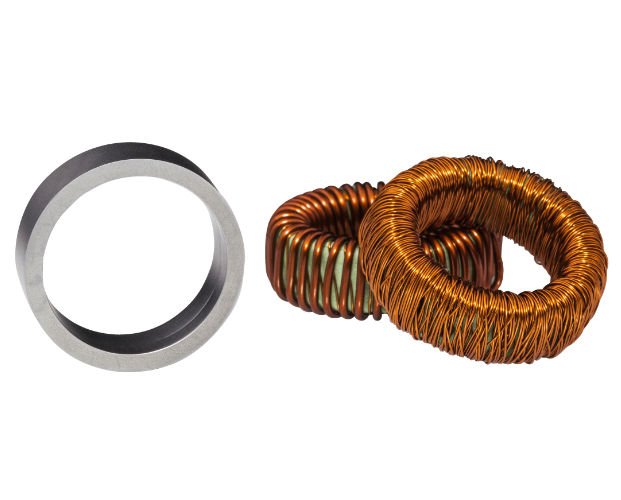

Electrical Resistance Alloys

Low TCR and high thermal stability for consistently reliable resistors

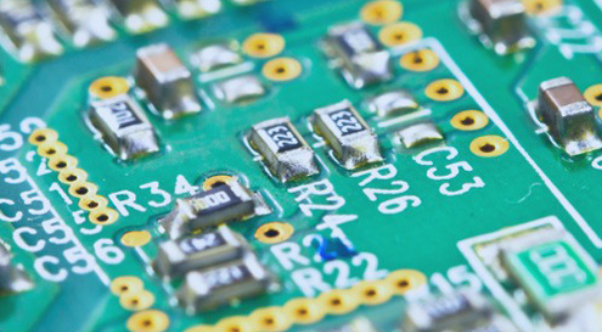

An integral part of electric vehicles, the battery management system (BMS) monitors the current and voltage throughout charging and operating cycles.

We enable the most efficient battery management systems with increased reliability through the low TCR of our high-performance materials. The high thermal stability of Evanohm® R enables precise operation of high power devices across a wide range of temperatures.

The Lowest Temperature Coefficient of Resistance Available

Sensors and control systems in electric vehicles and precision instruments, as well as aerospace and defense systems, must provide highly accurate electrical measurements at high operating temperatures. These electrical circuits require a low temperature coefficient of resistance (TCR) from resistors to operate reliably, and Evanohm® R has the lowest value available.

Evanohm R provides highly stable electrical resistance across a wide range of operating temperatures, remaining stable up to 200°C. This makes it highly effective in high-power mobility applications, such as electric vehicles. Battery management systems that feature Evanohm R resistors regulate voltage and current more precisely.

Evanohm R is well suited for additional applications that require precise measurements across a range of operating temperatures Strain gauges, for instance, require a low TCR to obtain accurate measurements for balance systems and structural health monitoring in aerospace, bridges, buildings, and more.

%20%20Datasheet.png)

Greater Adaptability for Resistor Design

An oxidation-resistant steel with a high specific electrical resistance as well as resistance scale. No. 1 JR® has a low temperature coefficient of resistance (TCR).

The available types have different electrical resistivities for greater adaptability for resistor design. No. 1 JR alloys are typically used in electric wire wound, edge wound and dynamic braking resistors. The corrosion resistance properties of this alloy are suited for high reliability under severe operating conditions.

Precise Output at High Temperatures

Our material solutions provide the lowest temperature coefficient of resistance (TCR) in their class of resistance alloys.

Long Term Stability

The properties of Evanohm® R remain exceptionally stable over time.

Consistent Reliability

Gain superior reliability when it comes to current and voltage sensing, as well as strain measurement.

Our engineering team works together with designers and production to ensure our resistance alloys meet specific processing and test requirements. We're ready to help with integration for your high precision circuit designs.

Browse our knowledge base of technical electrification resources: white papers, brochures, datasheets, webinars, and more.