PRODUCTS

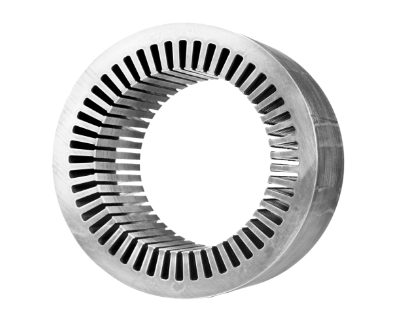

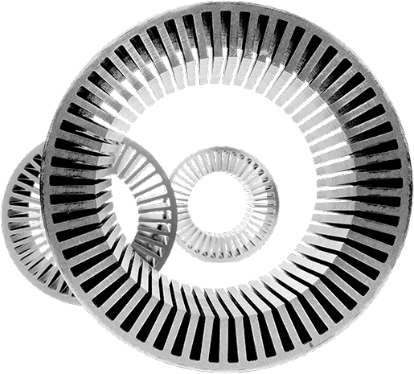

Build your advantage using our high-performance soft magnetic alloys and stator and rotor stacks.

Build your advantage using our high-performance soft magnetic alloys and stator and rotor stacks.

Advancing electrification through high-performance solutions for power-dense motors.

Creating solutions that enable the electrification revolution

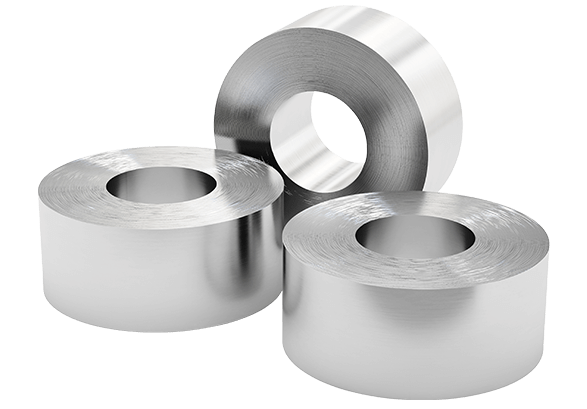

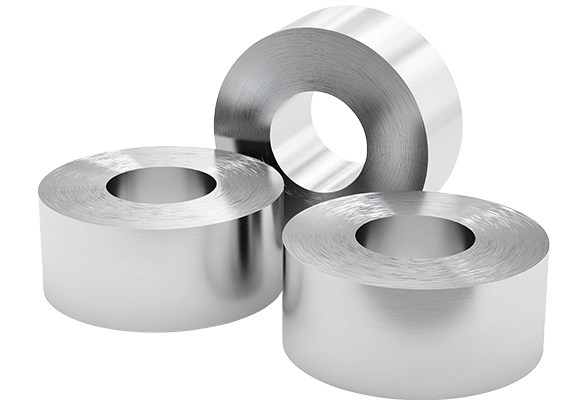

Soft Magnetic Alloys

High induction, high permeability, and low core loss soft magnetic alloys for device performance benefits, miniaturization, and product development flexibility.

Carpenter Electrification soft magnetic materials are used in over 75% of all generators and APUs installed on commercial and defense aircraft.

With a production capacity of over 100,000 tons per year and continuing strategic investments in electrification, we are a trusted partner when it comes to developing alloy, as well as stator and rotor stack breakthroughs.

Our Hiperco® alloys provide the highest magnetic induction of any commercially available soft magnetic material while exhibiting high permeability and low core loss.

These iron-cobalt alloys offer nearly 25% higher induction and 30% lower losses than conventional electrical steel and are available in thicknesses from 0.1 to 0.5mm. We work with customers to tailor mechanical properties based on their application needs.

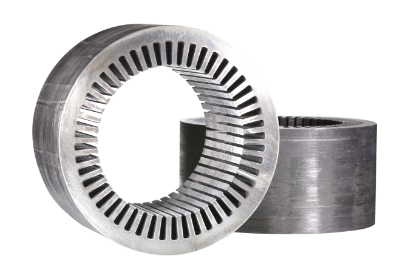

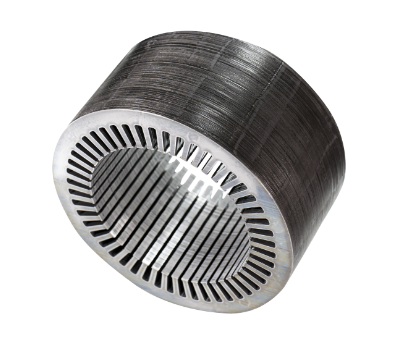

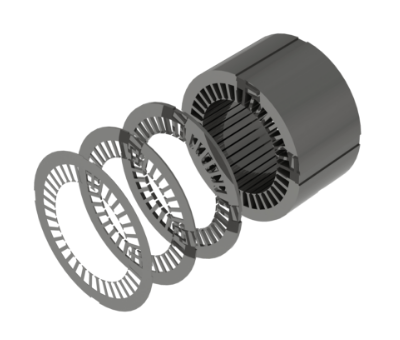

Hiperco alloys are used in motors and generators to achieve a combination of maximum torque density and the lowest losses. They offer significantly higher power and torque density as compared to conventional electric steels. They help improve motor efficiency and typically reduce the size and weight of the motor or generator.

Hiperco alloys also work as flux concentrators in electromagnetic pole pieces for different high flux applications, such as audio voice coils and medical radiology. These alloys are also used in actuators, specialty transformers, magnetic bearing applications.

Our Hiperco® alloys provide the highest magnetic induction of any commercially available soft magnetic material while exhibiting high permeability and low core loss. These iron-cobalt alloys offer nearly 25% higher induction and 30% lower losses than conventional electrical steel.

Our Hiperco® alloys provide the highest magnetic induction of any commercially available soft magnetic material while exhibiting high permeability and low core loss. These iron-cobalt alloys offer nearly 25% higher induction and 30% lower losses than conventional electrical steel.

Hiperco 50A has been optimized to provide the highest permeability and lowest losses as compared to other alloys in the Hiperco 50 family. It has been used for stator applications and magnetic cores in electrical equipment requiring high permeability at high magnetic flux densities. It has also been used in tape cores where lowest A.C. losses and high permeabilty at high inductions are desired.

Our Hiperco® alloys provide the highest magnetic induction of any commercially available soft magnetic material while exhibiting high permeability and low core loss. These iron-cobalt alloys offer nearly 25% higher induction and 30% lower losses than conventional electrical steel.

Hiperco 50HS is tailored for an optimum combination of magnetic and mechanical properties to withstand high stresses encountered in service. Hiperco 50HS is capable of producing a higher yield strength than conventional Hiperco 50 alloy. It has been used primarily in laminations for high-speed generators and magnetic bearings. Rotors produced from Hiperco 50HS meet demanding strength requirements with minimal sacrifice of magnetic performance. Their high power density enables the miniaturization of generators under these operating conditions.

Carpenter Technology’s Hiperco® 27 alloy provides high magnetic induction along with high thermal conductivity. This alloy is a good choice for haptic engine actuators, speakers, and motor generators.

Carpenter Technology’s Hypocore® offers high magnetic induction and low losses. This alloy offers 3-4% higher induction and 15-20% lower core losses than conventional electrical steel.

These properties result in higher torque, higher continuous power, lower heat generation during operation for easy thermal management, and significantly increased motor life.

High Permeability 49 has very high magnetic permeability, low core losses, and good magnetic induction. It is the ideal alloy for high-speed, high-efficiency motor design. It is easy to stamp and form into stators and rotors when compared to other high permeability soft magnetic alloys.

Given the high permeability, this alloy is frequently used for magnetic shielding and sensor applications.

HyMu 80 has superior permeability and low core loss. It is an ideal choice for ultra-efficient high-speed motors.

Given the very high permeability, HyMu 80 is a good candidate for magnetic shielding and sensors.

Silicon Core Iron B-FM is a modified free-machining alloy offering improved machining characteristics with no sacrifice in magnetic properties. It displays lower residual magnetism, higher electrical resistivity, and is more magnetically soft when heat treated.

Silicon Core Iron B-FM is melted in electric arc furnaces to exacting chemical specifications and carefully controlled through all manufacturing processes to produce a fine-grain, uniform quality magnetic core iron. This alloy should be considered for use in applications requiring a magnetic core component superior to mild steel, magnetic iron (99.2% Fe minimum), and a 1% silicon core iron.

Increase torque without altering your motor design

Our soft magnetic alloys offer up to 25% higher torque as a drop-in solution in current motor designs.

Improve efficiency and power density

With lower losses, our soft magnetic alloys can increase motor efficiency by up to 3% and power density by 30%.

Decrease motor size without sacrificing torque

Our power-dense alloys offer high-performance motors and up to 30% reduced footprint.

Improved thermal management and motor life

With our alloys motors run 10-20°C cooler during operation, offering better thermal management options and improved motor life.

Our engineering team partners with designers to ensure the maximum benefits of high performance soft magnetic alloys are realized.

We're always ready to consult on your motor design and integration, and stack production. Our experts help customize solutions to your specific product and application needs, ensuring your products reach peak levels of performance.

Browse our knowledge base of technical electrification resources: white papers, brochures, datasheets, webinars, and more.