Over the last few years supercars began to use electric motors as an alternative to internal combustion engines. We all take notice at the roar of an engine when it cracks the air. The sound is an unmistakable signal of power. Yet supercars using today’s quiet electric motors can outperform ICE based models when it comes to power and speed.

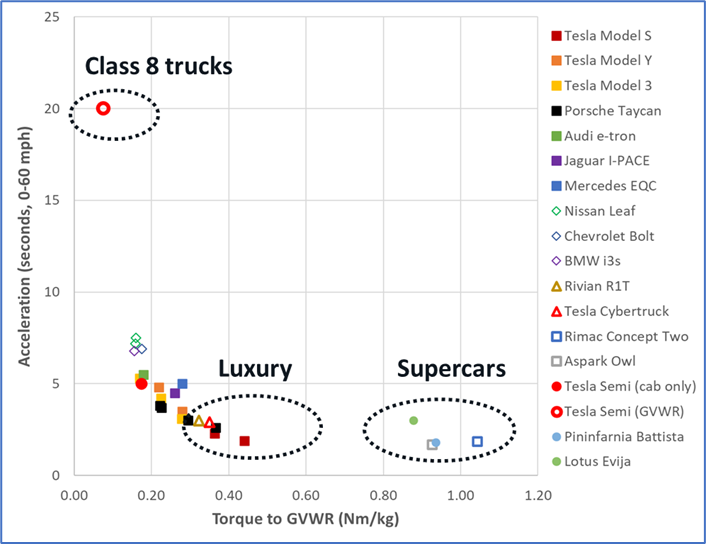

The performance demands of supercars dictate they use the most advanced technology. Comparing acceleration versus torque to gross vehicle weight rating (GVWR) provides guidance on the technology required. The chart of various EV models (based upon published data) highlights that supercars require high torque but from a lightweight and small electric motor set.

Electric supercar producers are evaluating and incorporating a variety of electric motor designs to maximize the torque and power density. These motors typically incorporate FeCo alloys given their higher permeability and magnetic saturation which deliver a 20-30% performance improvement as compared to electrical steels. Designing with FeCo alloys ensures the hair-raising power, acceleration, and speed in a small motor that provides design freedom for the exotic styling prized in these cars.

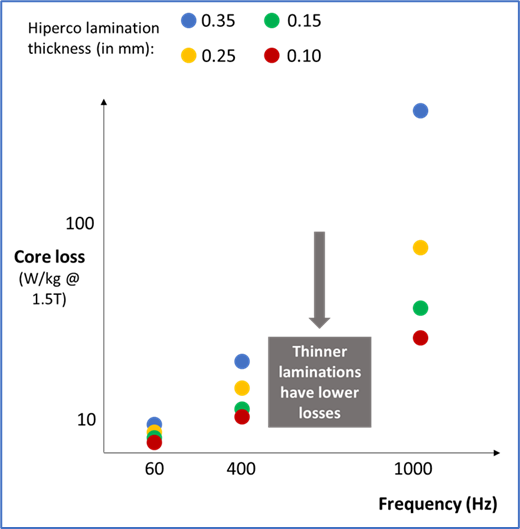

To maximize the power density, supercar electric motors may operate at higher frequencies than typical EVs. At these higher frequencies, stator and rotor iron lamination losses become the dominant factor limiting the motor responses. The impact of iron losses can be reduced by moving to thinner alloy laminations (see figure 2). A number of supercar designs are using FeCo laminations 0.15mm in thickness and lower. This technology provides the exceptional torque and power dense performance in a highly efficient motor with small form factor.

The Hiperco® 50 family of alloys provides the highest magnetic permeability and saturation of all FeCo alloys available in the market today. It is an ideal choice for the electric motors used in supercars. Producing motors for supercars using 0.15mm and thinner laminations requires precision processing to guarantee the highest magnetic properties of the stator and rotor stacks. Carpenter Electrification is expert in the alloy production and stack processing techniques required to maximize the performance of electric motors used in supercars and other electric vehicles.